Shaanxi Xianyang Chemical 600 thousand tons /year coal-to methanol project, lock hopper valve and three-way ball valve maintenance .

Valve service condition

The special requirements of lock hopper valve

High temperature----operation temperature reach 130~270℃.

High pressure--- working pressure :4.0~8.7MPa

Abrasion ----Glass slag will make the body and seat attrited , it will enter into the back of valve seat ,valve cavity and the bearing area, even lock the valve(This is the most common problem of lock hopper valve )

ANSI Class V 密封

High rating of seat seal ---ANSI Class V seal

Corrosion---Slag water may contain corrosive components, there are NACE requirements.

High strength--valves operated frequently, requiring high-strength bearings, strong ,durable structure.

Quick action ---Travel time 5-10 seconds.

Valves must work reliably for long periods of time .

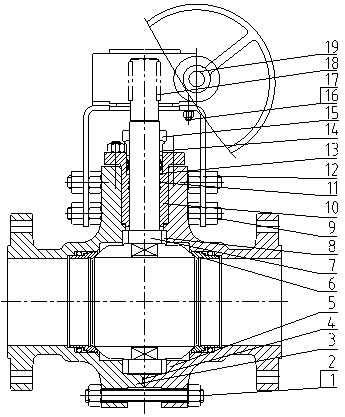

The structure of the fractional lock slag ball valve

1—bolt; 11—O-ring;

2—Nut; 12—Support;

3—Left valve body; 13—Packing;

4—Gasket; 14—Pressing sleeve;

5—Right valve body 15—Pressing plate;

6—Valve seat; 16—Stud;

7—Steam; 17—Nut;

8—Shaft sleeve; 18—Key;

9—Stud; 19—Gear box;

10—stuffing box;

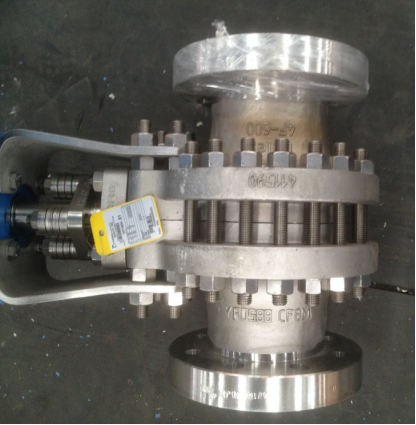

Xianyang Chemical lock hopper valve

After valves arrived our factory , we find the painting of the surface was seriously detached , the threaded fasteners rusted that it could not be rotated and the surface of the passage was slagging severely . What we do first is do treatment of the valve surface and fasteners for the further dis assembly work.

After dis assembly, the valve inner cavity is coking seriously .it should be cleaned to check the damage situation of every parts.

The valve interior ,ball and flow channel are damaged seriously . the edge of ball has been washed out by the medium , the seal is completely damaged and the packing is wear and tear severely.

Organize the professional technician for the scientific maintenance methods according to the damage situation of valves. Design and proposal the different maintenance methods, engineering department plan the assembly method of the spare parts.

technician surveying and mapping for the spare parts , workshop processing according to the the drawing .

The valve is repaired in the workshop

After prepare the spare parts , assemble the valves according to the assembly procedure .

Do the sealing test of each valve after finish the assembly, and the result of the testing need to be satisfied with the valve sealing standards and customer requirements.

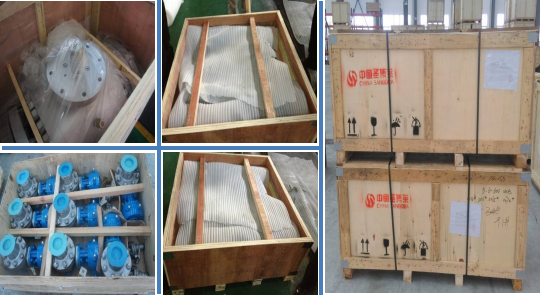

Painting and packing after the pressing test is qualified.

Valve service at site and the customer feedback.

PERRIN Wear-resistance ball valve of Ningbo Wanhua

After check we find the surface of valve interior ,ball and stem are corroded severely , the seals and some small spare parts are missed , it should be designed and calculated by the technician ,and looking for the manufacturer which is matched to customize valves .

Maintenance method of PERRIN Wear-resistance ball valve

Valve body, valve cover need to do pickling treatment and keep cleaning , avoid collisions .

After cleaning ,technician measure every part of the valves, keep and mapping the data of dimension ,material and harden depth(if existing )

Those valves with severe scratches on the ball , corrosion and fall off of hardened layerneed to be re-welded and hardened coating .

Make the drawing refer to surveying and mapping data and submit it to the production department for processing . According to the drawing data, the production department uses the lathe to turn off the original spray-welded layer and after finish turning, wait for the spray welding process.

The original valve seat has serious dirt and rust, and the sealing surface is deeply scratched. It is necessary to re-measure and make a new valve seat. The production department uses the lathe to turn the original spray welding layer according to the drawings and do welding treatment after finish turning .

The packing of valve stem ,sealing ring , O-ring and rear spring of valve seat can not be used any more. After surveying and mapping , replace the soft or metal seat , replace the failed spring ,check and maintain the turbine actuator, etc.

Do static pressure of valve ball and seat, initial grinding ,fine grinding and paired grinding to ensure that tight cooperation between the ball and valve seat.

The material of seat spring should be X-750 .

Machined and flange sealing surface.

Repair welding the corrosion of stem, replace the deformed stem .

The material of stem should be 17-4PH.

Replace all seals,customize the molding and forming (middle flange seal ,upper cover seal ,lower cover seal ,seat seal,etc,) Material of seals should be flexible graphite.

Replace partial upper and lower bolts . Material of Bolts should be A193-B8.

Test the torque of valves, configure the operating rod or worm gear operation :clean the worm gear completely and fill the grease.

Assembly and commissioning,test pressure to check the sealing performance .

VTI High temperature and wear resistance ball valve of Shenhua Shanghai research institute

After receive and inspect the valves, the gasket and packing could not guarantee the sealing because of high temperature ablation ,the threaded fasteners could not be rotated because rusted, the surface of channels was slagged seriously , ball and seat were corroded severely . The project used at site lasts 18 months since repaired by Sanbora.

After inspection , the valves seals were corroded seriously , the threaded fasteners could not be rotated because rusted, ball and seat were corroded seriously. This batch of valves assembled and used in May of 2012 after repaired by Sanbora and customer reflects these valves meets their requirements .

Maintenance of Dalian terminal station cryogenic top-entry ball valve

After inspection , the internal leakage of valve is serious that can not meets the customer requirements. It is necessary to process and grind the ball , seat and sealing parts. This batch of valve assembled and used in September of 2015 after repaired by Sanbora, and it is operating stably at the customer site.